They are sturdy, so they can support heavy lights, and other equipment that need to perform brightly and safely. Ever wondered how in heaven lighting trusses are manufactured and constructed? In this article, we take a deep dive into the world of heavy-duty lighting truss designs and discuss some general guidelines concerning structural integrity, material choices, load capacity, CAD software tools and somewhat sustainable methodologies.

Heavy-Duty Lighting Truss Designs: Unleashing the Secrets of Their Structural Integrity

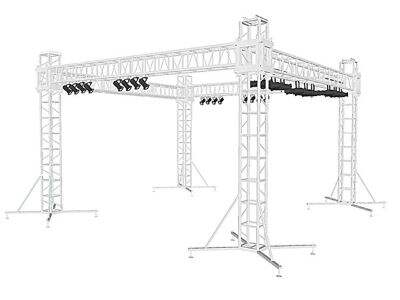

Lighting trusses in this category are heavy-duty, and constructed with the purpose of being strong and sturdy. They are typically created from materials like aluminum goes well with light weight and steel is considered to be more durable. A trussing for lighting consists of bars, or beams that are placed in such a way that the weight of the lights and equipment is better disbursed. This prevents the truss from bending or breaking with the heavy weight. Without sacrificing strength to weight, engineers do the math (and science) ensuring it can handle everything it has coming its way when picking a design for every lighting truss.

Development in material choices for Heavy-Duty Lighting Truss Construction;

Throughout the years, there have been countless material advances in heavy-duty lighting truss construction. Trusses, for instance, can be made from carbon fibre resulting in being lighter and stronger than trusses that use traditional materials such as aluminum. This means their design is more flexible and they also are easier to transport. So engineers are always searching for new materials they can use to make lighting trusses that much stronger and that much more efficient.

Lighting Truss Engineering Load Capacity and Safety Factors Explored:

Load bearing is an important parameter in the technical design of lighting trusses. Engineers must calculate the maximum load a truss can support, considering factors such as where lights are angled down to the stage, pressure from wind bouncing off it and vibrations of performers moving up and down, side to side. Safety is paramount with truss with lighting, lose a light in a unit and someone could be hurt or their property. This is why engineers specify a relatively high safety factor so the truss can survive unanticipated stresses and prevent it all from collapsing.

How CAD Software Helps Design and Test Heavy-Duty Lighting Trusses:

As a computer-aided design (CAD), heavier lighting trusses that are tested and used in designs. Truss designs are also rendered in 3d in a CAD program, showing what the truss will look like as well as perform once built. NES is capable of simulating various stress situations and adjust to refine the design for strength as well energy efficiency. With the aid of CAD, an engineer can spot potential problems and resolve them early to finalize a better version of their truss.

The Establishment: Heavy Duty Lighting Truss Manufacturing and Installation in a Sustainable and Efficient Way:

An increasing emphasis has been placed on sustainability in the manufacture and erection of heavy duty lighting truss, in recent times. Companies like Yiqian have been working towards waste reduction, energy conservation and emission mitigation of greenhouse gas in the production process. These efforts include working with recycled and sustainable materials, refining manufacturing processes and advancing transportation efficiencies. Companies choosing to prioritize sustainability are working towards both preserving the environment, and forming a more eco-friendly industry for tomorrow.

So remember, when it comes to heavy-duty lighting truss designs, the engineers are adhering t0 science and some downright inventive creativity. Everything from the structural integrity and material selection to load capacity, CAD software, and sustainability have a hand in producing reliable and robust lighting trusses for large-scale events. Thanks to their never-ending pursuit of design, and pushing the limits of modern technology, engineers are helping light truss manufacturers pave a brighter and more environmentally friendly future.

Table of Contents

- Heavy-Duty Lighting Truss Designs: Unleashing the Secrets of Their Structural Integrity

- Development in material choices for Heavy-Duty Lighting Truss Construction;

- Lighting Truss Engineering Load Capacity and Safety Factors Explored:

- How CAD Software Helps Design and Test Heavy-Duty Lighting Trusses:

- The Establishment: Heavy Duty Lighting Truss Manufacturing and Installation in a Sustainable and Efficient Way: